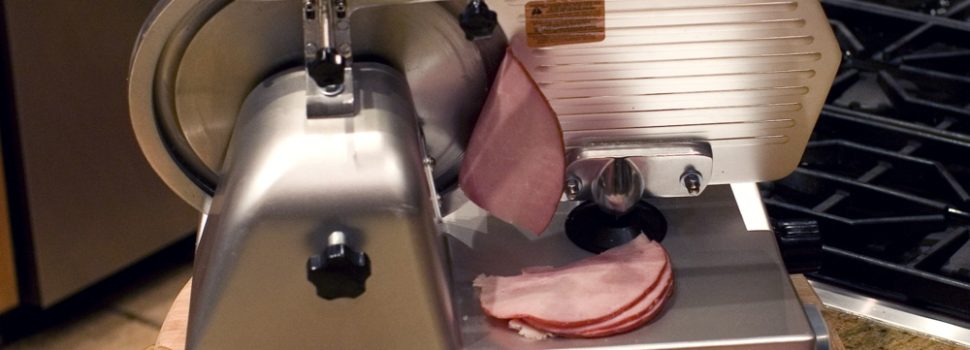

All day I dream of fresh deli meats. The sweet tavern hams, the pastrami, prosciutto, and even fresh bologna. Just the idea of freshly sliced meats can make my mouth water. Then you remember the hours of waiting in line at the deli, or buying pre-packaged containers of meat loaded with salt and preservatives. There is an another option for fresh sliced cheeses, fruits, vegetables, and meats, however.

Be like Kramer and get your own deli meat slicer! Whether you’re a professional chef, caterer, or home cook, a meat slicer is an essential kitchen tool for the thinnest cuts of meat. A deli meat slicer allows you to slice meat and other food items quickly, efficiently, and with the greatest of precision. But with so many options on the market, shopping for a deli meat slicer can be overwhelming.

In this best of all times to be alive, owning your own deli meat slicer is an achievable reality. They’re very reasonably priced – your local home improvement stores has them available for less than a few hundred dollars. Different models of deli meat slicers can handle various types of loads, from slicing through lean turkey breast to dense blocks of cheese. This makes getting the right deli meat slicer very important.

What to Consider When Purchasing a Deli Meat Slicer

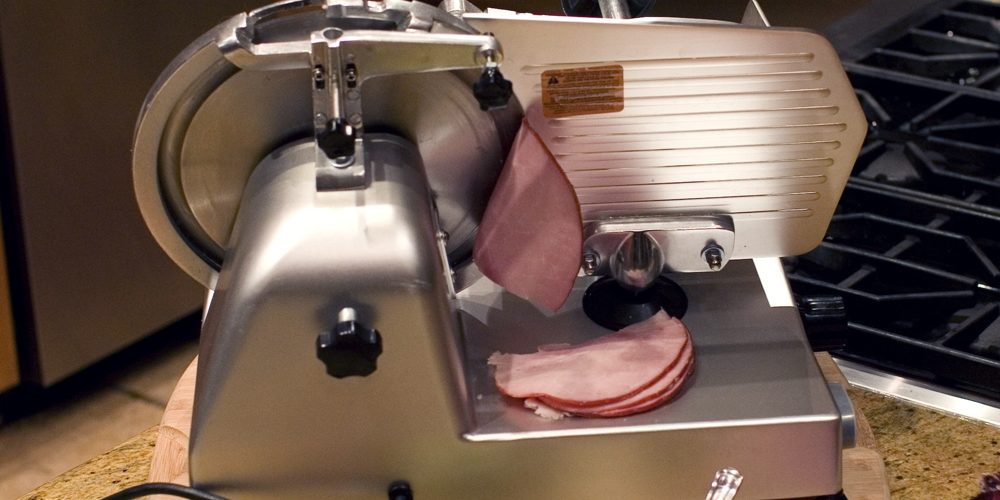

Many factors come into play when making your purchase. Things like horsepower, blade size, or whether the meat slicer is driven by belts or gears. Then you will need to decide whether you want a manual or automatic slicer. Automatic slicers are safer and provide for better multi-tasking. However most users will prefer manual slicing. Before you purchase your deli meat slicer, try to take it for a short test drive. From small skin mole removal to plates of freshly sliced gourmet cheese, a deli meat slicer adds a tremendous value to your kitchen.

Entry Level Slicers are best suited for operations where the slicer would be used for an hour or two at most per day. While designed for simple, safe operation, they are not recommended for slicing cheese, and do not offer as many safety or convenience features as higher-end models. They are not meant for cutting raw or frozen meat or cheese.

Mid-Tier Slicers generally have larger blades, a bit more horsepower, and can withstand more constant use than an entry-level model. Some models can handle occasional slicing of cheese, but are primarily intended for a few hours of vegetable or deli meat slicing per day. They usually offer a few more safety and convenience features than an entry-level model too.

Premium Slicers represent the top-of-the-line offerings from each manufacturer. Most are designed for heavy duty, constant use, and can slice cheese as well. These models offer design features that enhance the smoothness of operation, slice precision and safe operation. These deli meat slicers are the top of the line slicers designed for use at big restaurants. They are the type of slicers found in butcher shops and other meat markets because they can handle just about anything.

Blade Size and Horsepower

Mid tier and premium slicers usually have larger cutting blades (12″-14″) for all-around use, whereas entry level models often use smaller cutting blades (9″ and 10″) for lighter use. Industry-wide, a 12″ cutting blade is the most common size. When it comes to picking the size of your blade, you have to consider the volume of the food that you will be slicing with the blades. For smaller restaurants, your blade size should be 8 or 9. If you will be slicing larger volumes of food, your blade size can be anywhere between 9 and 14.

Anyone that has used a meat slicer knows how important the blades are. If you intend to buy a slicer, you should make sure that the slicer comes with stainless steel blades because stainless steel blades do not rust and can cut through almost anything. You should also make sure the slicer has a built-in sharpener for the blades to keep them razor sharp.

As for horsepower the more you use it the more horsepower you will want. Calm down Tim the Tool Man, be realistic in your HP needs. Generally, higher horsepower slicers are designed for more frequent use.

Manual vs. Automatic?

An automatic slicer, where an electric motor moves the product tray back and forth, is convenient when slicing large amounts of product because it can slice continuously without constant staff assistance. Automatic slicers can also be operated manually, so the main deciding factor is how much slicing you do. Large delis or supermarkets would see the most benefit from an automatic slicer. Automatic meat slicers are very fast, since the slicers are automatic, you don’t have to slice the meat by yourself.

All you have to do is feed the meat into the machine and let it do the rest. Automatic slicers are turbo charged and can cut up to 60 slices per minute. As expected, these are the most expensive types of meat slicers available, and are only worth the price tag if your business involves a lot of meat slicing.

What about belt driven or gear driven? Nearly all of the great slicers are belt driven. In theory, a slicer with a gear driven blade will be more durable, but in actual practice, if your gear-driven slicer does require a repair, it will cost a lot more than simply replacing a drive belt.

No comments so far.

Be first to leave comment below.